Fine mixing solutions made simple

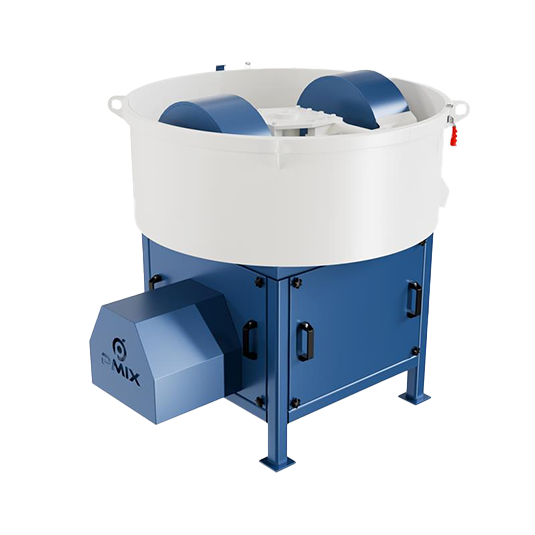

The Muller Mixer is renowned for its superior mixing and kneading capabilities, making it the preferred choice for industries such as foundries, pharmaceuticals, and mineral processing. Our Muller Mixer excels in achieving thorough blending and uniform distribution of ingredients.

Contact Us

What our Muller mixers do best

Discover the cutting-edge features that we offer to you with our mixers. We focus towards providing you with utmost value in a cost-efficient manner, making sure that you get the best products at their best price.

Contact UsTop Cover

The Muller Mixer includes a top cover to prevent material spillage and maintain a clean working environment.

Specialized Applications

The Muller Mixer is often used in industries that require gentle and precise mixing of abrasive materials..

Material options

Available in mild steel (M.S.) and stainless steel (S.S.) to suit various applications.

Robust construction

Features two heavy-duty rollers and three scrapers for efficient mixing.r.

The qualities that fuel our endeavours

Innovation

We continuously strive to innovate our solutions, making sure that we place a key emphasis on adapting to the latest trends in the market. This way, we stay competitive and undergo constant evolution.

Expertise

With a key focus in R&D, we’ve employed the finest engineers so that you can get nothing but the best solutions. Our engineers form the heart of our product, and are experts at what they do!

Reliability

PMIX provides a long-standing commitment to providing top-notch quality solutions to customers like you. This means that we guarantee reliability with mixers that can withstand the test of time.

Customization

Our mixers can also be customized in a variety of ways. You have the option of customizing our mixers to your usage. We understand that different industries have different needs, so we work towards making sure we meet them.

Any industry, many applications

Thanks to versatility of our mixers, we can cater to a range of industries with numerous applications. The advanced features of our mixers deliver exceptional performance and consistent mixing results.

Technical specifications:

| Particular | Model | ||||||

| MM 60 | MM 100 | MM 120 | MM 135 | MM 150 | MM 180 | ||

| Capacity | 50 kg | 100 Kg | 150 – 200 Kg | 200 -250 Kg | 300 Kg | 500 Kg | |

| Electric Motor | 2HP, 50Hz, 3Phase | 3HP, 50Hz, 3Phase | 5 HP, 50Hz, 3Phase | 7.5/ 10 HP, 50Hz, 3Phase | 15/ 20 HP, 50Hz, 3Phase | ||

| Loading Height | 950mm | 1095 mm | 1140 mm | 1650 mm | |||

| Discharge Height | 400mm | 485 mm | 450 mm | 840 mm | |||

| All over dimension (LWH) in mm | 635 X 800 X 1100 | 1058 x 1122 x 1095 | 1298 x 1258 x 1095 | 1450 x 1447 x 1140 | 1600 x 1558 x 1140 | 1900 x 2100 x 1650

|

|

| RPM | 24 | ||||||

| Note:

· Can be customized as per specific needs · Due to continuous development in the design, specification and dimensions are subject to change without prior notice

|

|||||||

Why choose PMIX?

Roller-Based Mixing

The Muller Mixer utilizes rollers for mixing, providing a gentle and effective approach for sensitive materials..

Ideal for Abrasive Materials

The roller-based design is particularly well-suited for mixing abrasive materials, such as ceramics and refractories..

Don’t just stir it, be the mixing master with PMIX

Are you looking for precision and consistency in your mixing processes? Get this perfect blend with PMIX mixers.

Contact Us